Sharpening vs honing, are two essential processes for maintaining the sharpness and performance of cutting tools. While they are often used interchangeably, they are distinct techniques with different purposes. In this article, we will explore the difference between sharpening and honing, why it matters, and how to effectively use these techniques to keep your tools in optimal condition.

1. Introduction

Maintaining sharp tools is crucial for achieving precise and efficient results in various tasks, whether it’s cooking, woodworking, or crafting. Sharpening and honing are the two primary methods used to restore and enhance the cutting edges of tools like knives, chisels, plane blades, and scissors.

2. Understanding Sharpening

What is sharpening?

Sharpening is the process of removing material from the blade or edge of a tool to create a new, sharp edge. It involves grinding or abrasive methods to reshape the cutting edge and restore its original geometry.

Importance of sharp tools

Sharp tools provide several advantages, including:

- Enhanced cutting performance: Sharp edges cut more effectively and with less effort, resulting in cleaner and more precise cuts.

- Increased tool control: Sharp tools allow for greater control over the cutting process, reducing the risk of accidents or damage.

- Extended tool lifespan: Regular sharpening helps prevent excessive wear and tear, prolonging the lifespan of the tool.

3. Understanding Honing

What is honing?

Honing, on the other hand, is the process of refining and polishing the cutting edge to achieve optimal sharpness. It involves using finer abrasives or stones to remove microscopic imperfections, align the edge, and enhance its cutting properties.

Honing vs sharpening

While sharpening focuses on restoring a blunt or damaged edge, honing aims to maintain an already sharp edge and refine it further. Honing is often performed more frequently than sharpening to keep the tool in peak condition.

4. Sharpening vs Honing: Differences

To understand the difference between sharpening vs honing, let’s consider the techniques involved and the effects on the cutting edge.

Techniques used in sharpening

Sharpening typically involves more aggressive methods, such as grinding on a sharpening wheel or using sharpening stones with coarse grit. It removes a significant amount of material to create a new cutting edge, making it suitable for repairing dull or damaged tools.

Techniques used in honing

Honing employs finer abrasives or stones with higher grit to refine the edge without removing as much material. It focuses on polishing the existing edge, removing any burrs or irregularities left from sharpening and aligning the edge for optimal performance.

Effect on the cutting edge

Sharpening produces a new, sharp edge by reshaping the blade while honing maintains and refines the existing sharp edge. Sharpening removes more material, resulting in a more aggressive cutting edge suitable for heavy-duty tasks. Honing, on the other hand, creates a finer and more precise cutting edge, ideal for tasks that require precision and delicate cuts.

When to sharpen and when to hone

Knowing when to sharpen or hone your tools is crucial for maintaining their performance. Generally, sharpening is necessary when the tool has become dull, damaged, or has a significant loss of cutting efficiency. Honing, on the other hand, is performed more frequently to maintain the sharpness of a tool between sharpening sessions. Regular honing helps keep the tool in optimal condition and extends the time between sharpening.

5. Benefits of Sharpening

Increased cutting efficiency

Sharpening your tools enhances their cutting efficiency. A sharp edge cuts through materials with less resistance, allowing you to complete tasks faster and with greater ease. Whether you’re slicing ingredients in the kitchen or working on a woodworking project, sharp tools make the process more efficient.

Improved tool performance

Dull tools can lead to frustration and subpar results. By sharpening your tools, you optimize their performance. They will cut cleanly, reducing the likelihood of mistakes or accidents. The improved performance will also give you greater control over the tool, enabling you to achieve the desired outcome with precision.

Extended tool lifespan

Regular sharpening can significantly extend the lifespan of your tools. When you sharpen your tools, you remove any nicks or imperfections that can cause premature wear. By maintaining a sharp edge, you reduce the likelihood of excessive force or pressure being applied to the tool, minimizing the risk of damage. A well-sharpened tool will serve you reliably for a longer period, saving you money on frequent replacements.

6. Benefits of Honing

Refining the cutting edge

Honing is essential for refining the cutting edge of a tool. It removes microscopic imperfections, aligns the edge, and enhances its sharpness. Honing is particularly beneficial for maintaining the performance of precision tools, such as chef’s knives or woodworking chisels. It ensures that the cutting edge remains consistently sharp, enabling you to achieve clean and accurate cuts.

Correcting small imperfections

Over time, even with proper sharpening, tiny imperfections can develop on the cutting edge. These imperfections can affect the performance of the tool and lead to subpar results. Honing helps correct these small imperfections by removing any burrs or irregularities, ensuring a smooth and flawless cutting edge.

Maintaining sharpness

Honing is not only about refining the edge but also about maintaining sharpness between sharpening sessions. As you use a tool, its cutting edge may gradually lose its sharpness due to normal wear. Regular honing helps restore and maintain sharpness, ensuring consistent performance throughout your work. It’s a proactive approach to keep your tools at their best without the need for frequent sharpening.

7. Sharpening vs Honing: Tools and Techniques

To achieve optimal results when sharpening and honing, it’s important to use the right tools and employ the correct techniques. Let’s explore some commonly used tools and methods for both processes.

Sharpening tools and methods

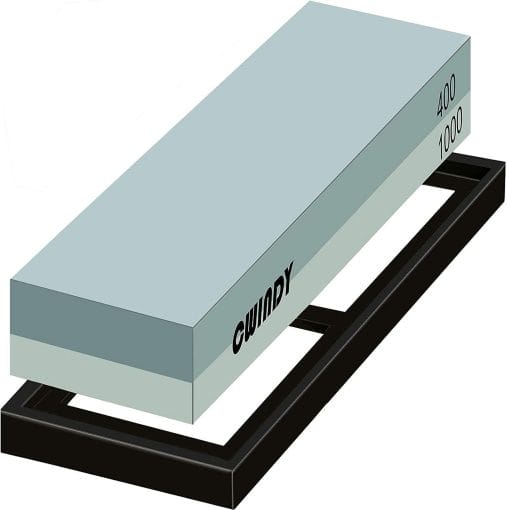

- Sharpening stones: These abrasive stones come in various grit levels and are used to remove material and shape the cutting edge. Coarse grit stones are used for initial sharpening, while finer grit stones are used for honing and polishing the edge.

-

Sharpening systems: Electric or manual sharpening systems provide a convenient and consistent way to sharpen tools. These systems often have built-in angle guides to ensure precise sharpening angles.

-

Grinding wheels: Grinding wheels are used for heavy-duty sharpening, particularly for larger tools like axes or lawnmower blades. They remove material quickly but require caution and proper technique to avoid overheating and damaging the tool.

Honing tools and methods

-

Honing stones: Finer grit honing stones, also known as whetstones, are used for refining and polishing the cutting edge. They remove any remaining burrs and provide a smooth finish to the edge.

-

Stropping: Stropping involves rubbing the tool’s edge against a leather or fabric strop coated with an abrasive compound. This process helps further refine the edge and achieve a razor-sharp finish.

-

Honing guides: Honing guides assist in maintaining consistent angles while honing. They hold the tool securely and allow for precise and controlled honing.

Popular sharpening and honing systems

-

Waterstones: Waterstones are popular for their versatility and effectiveness in both sharpening and honing. They provide excellent results when used with proper technique and regular maintenance.

-

Diamond stones: Diamond stones are known for their durability and ability to remove material efficiently. They are suitable for both sharpening and honing and offer a long lifespan.

-

Sharpening jigs: Sharpening jigs are useful for achieving precise angles and bevels during the sharpening process. They hold the tool securely and ensure consistent results.

Find some Sharpening and honing tools by clicking here:-

8. Tips for Effective Sharpening and Honing

To get the best results when sharpening and honing your tools, consider the following tips:

Choosing the right tools

Select sharpening and honing tools based on the specific requirements of your tools and the level of sharpening needed. Different grits and materials will yield different results, so choose accordingly.

Understanding angles and bevels

Become familiar with the optimal sharpening angles and bevels for your tools. This information can usually be found in the manufacturer’s guidelines or through research. Consistently maintaining the correct angles will ensure optimal cutting performance.

Practicing proper technique

Mastering the proper technique is crucial for effective sharpening and honing. Whether using sharpening stones, honing guides, or sharpening systems, practice the recommended motions and follow the instructions to achieve the best results.

Maintaining consistency

Consistency is key to maintaining sharp tools. Establish a regular sharpening and honing routine based on the frequency of tool use and the specific requirements of each tool. Regular maintenance will prevent tools from becoming excessively dull and reduce the need for aggressive sharpening.

9. Conclusion

Understanding the difference between sharpening and honing is essential for maintaining the performance and longevity of your cutting tools. Sharpening involves reshaping the cutting edge to restore sharpness while honing focuses on refining and maintaining that sharpness. Both processes are crucial for achieving clean, precise cuts and optimal tool performance. By selecting the right tools, practicing proper techniques, and maintaining consistency in your sharpening and honing routine, you can ensure that your tools remain in top condition for years to come.

Read out our most popular blog here:-

How to Use Wasabi Knife Sharpener

3 Best Professional Chef Knife Set With Bag 2023

FAQs

1. How often should I sharpen my tools?

The frequency of sharpening depends on several factors, including the type of tool and how frequently it is used. As a general guideline, it is recommended to sharpen tools when you notice a decline in cutting performance or when the tool becomes visibly dull.

2. Can I use the same sharpening tools for all types of tools?

While some sharpening tools are versatile and can be used for various tools, it is advisable to use specialized tools for specific types of tools. Different tools have different blade angles and requirements, so using the appropriate sharpening tools will ensure optimal results.

3. Is honing necessary if I already sharpened my tools?

Yes, honing is necessary even after sharpening your tools. Sharpening creates a new cutting edge, but honing helps refine and maintain that edge. Honing removes any remaining burrs or imperfections, resulting in a smoother and more precise cutting edge.

4. How do I know if my tool needs sharpening or honing?

If your tool is noticeably dull, struggles to cut efficiently, or produces rough or uneven cuts, it is likely in need of sharpening. On the other hand, if your tool is still relatively sharp but lacks its initial smoothness and precision, honing is recommended.

5. Can I sharpen and hone serrated blades?

Sharpening serrated blades can be challenging and requires specialized tools. It is recommended to seek professional sharpening services or use sharpening systems specifically designed for serrated blades. Honing, however, can be performed on serrated blades using a tapered honing rod or a ceramic honing tool to maintain their cutting performance.

6. Can I over-sharpen my tools?

While it is possible to remove excess material and compromise the structural integrity of the tool by over-sharpening, it typically requires significant effort and repeated sharpening sessions. With proper technique and attention, it is unlikely to over-sharpen your tools during regular maintenance. However, it is always advisable to follow the manufacturer’s guidelines and use caution when sharpening.

In conclusion, understanding the difference between sharpening and honing and knowing when to use each technique is crucial for maintaining the performance and lifespan of your cutting tools. By incorporating regular sharpening and honing into your tool maintenance routine, you can ensure sharp, precise cuts and enjoy the full potential of your tools for years to come.